Strength, ductility and toughness are three very important and distinct material properties, but understanding the differences between them can sometimes be confusing. This page and the video below should help clear things up!

Material Strength

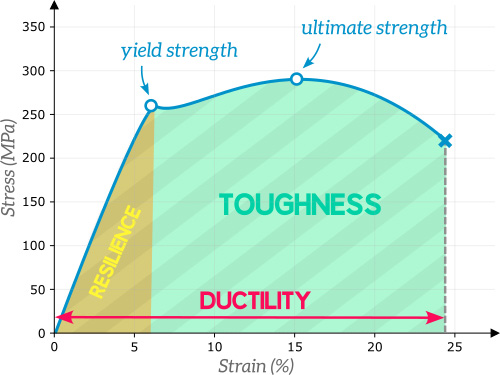

Strength is a measure of the stress a material can withstand. Two different measurements are used to define the strength of a material:

- The ultimate strength, which is the maximum stress the material can withstand before fracturing.

- The yield strength, which is the stress at which the material begins to deform plastically (meaning that permanent deformation remains after the applied load is removed).

Both the ultimate strength and the yield strength express how much force the material can withstand per unit area, so they have the same units as stress, which is force/area. In the SI system strength and stress have units of pascals (

Yield and ultimate strengths can be determined from the stress-strain curve of a material, that is obtained by performing a tensile test.

Many structures and components are design to ensure that they only deform elastically (i.e. there is no permanent deformation after the applied load is removed). This makes the yield strength a commonly used criterion for defining failure in engineering design codes. The failure theories page goes into more detail about the different ways failure is defined.

Here are some typical strength values for a few different materials.

| Material | Yield Strength [MPa] | Ultimate Tensile Strength [MPa] |

|---|---|---|

| Copper | 33 | 210 |

| Aluminium Alloy 3033 | 126 | 200 |

| Steel, stainless AISI 302 | 275 | 620 |

| Titanium 6Al-4V | 880 | 950 |

Determining the Yield Strength from a Stress-Strain Curve

The transition from elastic to plastic deformation is not always easy to identify on a stress-strain curve. For this reason standard methods have been developed to determine the yield strength from tensile test data. One of the more common methods that is often used for metals is the 0.2% offset method. Here’s how it works:

- Step 1 – draw a line with a slope equal to the Young’s modulus of the material

- Step 2 – shift this line 0.2% to the right on the stress-strain curve

- Step 3 – the intersection between this line and the stress-strain curve gives you the material’s 0.2% offset yield strength (also called 0.2% proof stress)

This process is illustrated in the image below. This material has a 0.2% offset yield strength of 330 MPa.

The Efficient Engineer Summary Sheets

The Efficient Engineer summary sheets are designed to present all of the key information you need to know about a particular topic on a single page. It doesn’t get more efficient than that!

Material Ductility

Ductility is a measure of the ability of a material to deform plastically before fracturing.

- A material is ductile if it undergoes a large amount of plastic deformation before it breaks. These materials fracture at very large strains. Examples of ductile materials include mild steel, aluminium, and gold.

- A material is brittle if it fractures at low strains with little or no plastic deformation. Examples of brittle materials include glass and ceramics.

The differences between ductile and brittle materials can be seen in the stress-strain curves shown below.

Ductile and brittle materials have very different stress-strain curves, with brittle materials exhibiting little or no plastic deformation before fracturing. Because they don’t deform plastically, the concept of yield strength is irrelevant for brittle materials.

Typically a material that has a strain at fracture of less than 5% is considered to be brittle.

Compressive vs Tensile Loading

Another interesting difference between ductile and brittle materials is how the behave under compressive versus tensile loading.

For ductile materials like mild steel the yield and ultimate strengths are very similar in the tensile and compressive directions. Compression tests are more difficult to carry out than tensile tests because buckling can be an issue, so compression tests aren’t often performed for ductile materials.

For brittle materials like concrete and ceramics the material strength is much larger in compression than in tension. Separate tensile and compression tests usually need to be carried out to properly characterised these materials.

DUCTILE MATERIALS

compressive strength

BRITTLE MATERIALS

compressive strength > tensile strength

Ductility vs Temperature

The ductility of a material can vary with temperature. A lot of different types of steel for example are ductile are room temperature but become brittle when the temperature drops to below the ductile-to-brittle transition temperature. This is an important design consideration because ductile failure is normally preferred to brittle failure.

Material Toughness

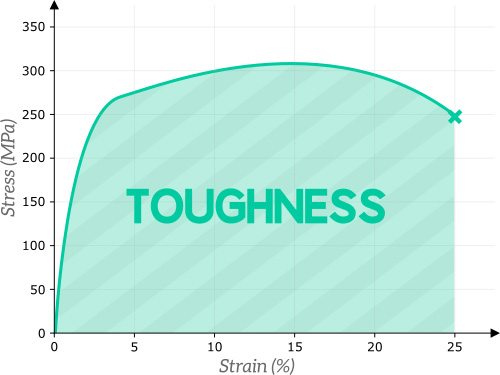

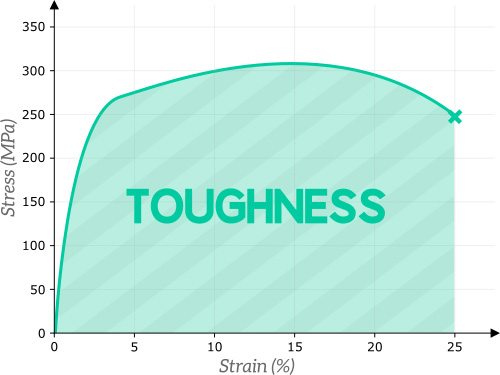

Toughness is the ability of a material to absorb energy up to fracture. Materials that can absorb a lot of energy before fracturing have high toughness.

Toughness can be thought of as the area under the stress-strain curve. If the area is large, the material will have high toughness and will be able to absorb a large amount of energy before fracturing.

For a material to have high toughness it should have a good balance of both high strength and high ductility. Low strength and brittle materials tend to have low toughness.

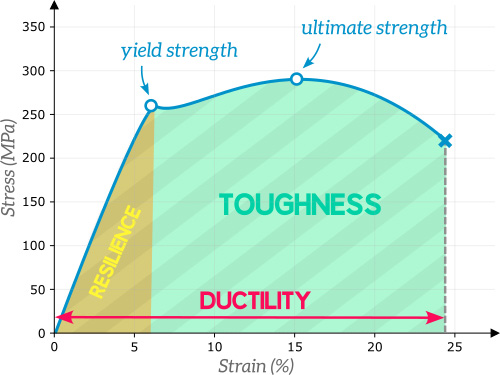

Strength vs Ductility vs Toughness

Strength, ductility and toughness are separate but linked material properties. The five boxes below summarise the definitions of these properties, and a fifth parameter, resilience, is introduced.

Ultimate strength

the maximum stress which is reached during the tensile test

Yield strength

the stress at which a material begins to deform plastically

Toughness

a measure of the ability of a material to absorb energy up until fracture

Ductility

a measure of the ability of a material to deform plastically

Resilience

a measure of the ability of a material to absorb energy while deforming elastically

These five properties can be identified on the stress-strain curve, as shown below.

Related Topics

Young's Modulus

Young's modulus is a measure of the stiffness of a material – it describes the relationship between stress and strain.

Stress and Strain

Stress and strain are fundamental concepts that relate to the internal forces and deformations within a body in response to applied loads.